Equipment

WIRE AND SINKER EDMs

- Sodick VL400Q with LN2W Control Wire EDM

- Sodick A3200 Wire EDM

- Belmont CNC Series 100 Model 126 CNC RAM EDM

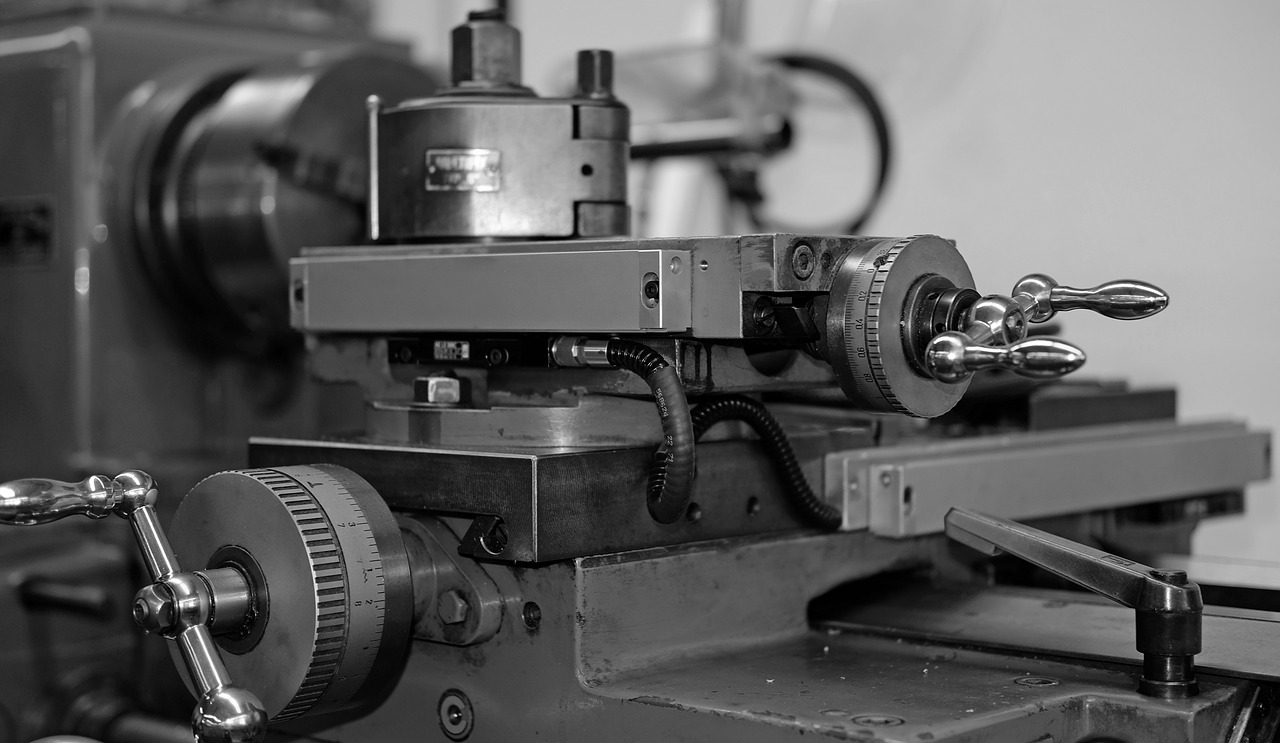

MULTI-AXIS TURNING

- Star SR-20R CNC Swiss type Automatic Lathe with Fanuc 181 -TA Controller

w/Thread Whirling - CH12HOU Turning Lathe

- Cincinnati Milacron Hawk 150 CNC Turning Center

- Haas CNC Lathe, Model ST-10

MULTI-AXIS MACHINING

- Okuma & Howa Millac 415V Machining Center with 4th Axis Rotary Table

- Haas VF-2 Vertical Machining Center w/4th axis

- 2 Haas VF-2 Vertical Machining Center w/4th axis Rotary Table

- 4 Haas Mini-Mill Vertical Machining Center

- Toolex-RWS^OOS Relock 8 Rotary Station Vise

- Bridgeport Turret Mill

FINISHING

- Kent Surface Grinder

- Hammond 5-VSDL Variable Speed Polishing & Buffing Lathe

- Hammond Belting and Polishing Machine

- 2 Baldor Buffing Machine

- Burr King #110 Vibratory Tumbler

- Trinco Master Split level Sandblaster with Abrasive Separator

- Cyclone Sandblasting System

- Lincoln Square Wave Tig 175 welder

- HT-1212 Ultrasonic Cleaning Tank

- Trumpf TruMark 6020 w/Trumark Station 5000 1064nm Laser Marking System

- Elma E300H Ultrasonic Cleaning Tank

QUALITY CONTROL

- 30″ OGP *XL-30C Optical Comparator

- 2 Mitutoyo Height Stand

- 2 Digimatic Height Gage 12″

- Microview 12″ Optical Comparator

- Suburban Master-View w/Quadra Check 2000 Comparator 14″

- Scherr-Tumico 14″ Vertical Beam Comparator

- Mitutoyo Coordinate Measuring Machines (External; accu-measure)

- Mitutoyo 14″ Optical Comparator (External; accu-measure)

- Surface plates up to 24”

- Calipers up to 18”

- Micrometers up to 10”

- Thread-ring gages to 5/8”

- Thread-plug gages 5/8″

- Gage pins to 1.0″

- Gage Blocks

All measuring equipment is part of a regulated calibration program meeting the requirements of MIL.C-45662 and MIL.STD-120.

ENGINEERING / PROGRAMMING EQUIPMENT

- SOFTWARE: Calibration Recall, Vellum, Win-CNC, BobcadCam, Solidworks Viewer, Master-Cam, SBM – Small Business Manufacturing